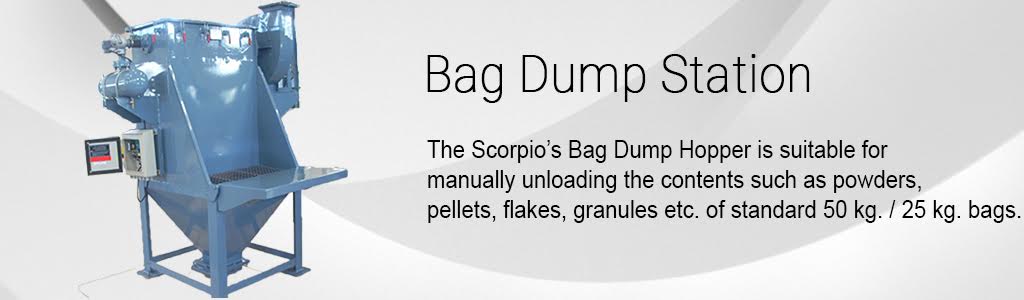

Bag Dump Station:

Finely powdered materials tend to create hazardous and unhealthy dust clouds at the unloading / discharging point and create pollution problems and material wastage. A simple and inexpensive solution is to use a Bag Dump station which allows convenient and dust free unloading of manually cut bags. The Scorpio’s Bag Dump Hopper is suitable for manually unloading the contents such as powders, pellets, flakes, granules etc of standard 50 kg / 25 kg. Bags.

Constructions:

It consists of an integral hopper into which contents of the bags are manually unloaded. The hopper is fitted with a mesh to separate thin and long fibres. A dust filter is mounted onto this hopper. The dust filter operates with a reverse pulsejet cleaning mechanism. Dust generated while emptying of the bag, is collected onto the filter bags and dislodged by the air pulses. A centrifugal fan mounted above the filter unit evacuates dust free air to atmosphere. This unit is available in both Mild Steel and SS304 contact parts.

Specifications:

- MOC: MS construction / SS contact parts

- Inlet grizzly: SS304 mesh of 1" Square opening

- Paint: Synthetic enamel paint - 100 DFT. (Optional: Epoxy paint)

- Filter Bags: Polyester needle felt. (Various filter membrane available for specific application)

- Control Voltage: 24V DC / 110V AC / 220V AC

- Filter Cleaning: Sequential reverse pulse jet cleaning mechanism

- Dust collector outlet dust Emission level - 10 to 15ppm.

- Noise level - 85dBA at 1 mtr distance.

- Centrifugal fan : 2.2 kW 415 V AC, 3 phase, 50 Hz.

- Starter: Optional

- Outlet valve : Optional

- Outlet ducting from fan : Not Provided